ORIGEN, the label for products that respect the environment and people's health

Since 1969, the year our company was created, Baixens has implemented different actions with the aim of significantly reducing the environmental impact of our products throughout their life cycle, from the time the raw materials are obtained to the end of their useful life, including their manufacture, distribution and use.

Likewise, since our beginnings, we have always been very clear that health is a social aspect upon which we can and must have an impact as a company. Our actions as part of society have an impact as much on the health of our employees as on that of all people, as environmental health and human health are closely linked.

All of these actions have now become a reality thanks to the implementation of the ORIGEN seal for our fillers and plasters.

The ORIGEN seal encompasses many of our emblematic products, which were consolidated in the market thanks to their innovative and/or efficient character and which have been improving their quality and environmental qualification thanks to the new technologies used in our R&D&I department.

But it is not only our flagship products that will be incorporating this sustainability seal. All our fillers and plasters are eligible for this, provided that they comply with highly demanding requirements regarding respect for the environment and people.

The quality of Baixens products has never been compromised by our commitment to the environment and people's health. This is highlighted by their enormous effectiveness, the innovative nature of many of them, the market and the professionals in the sector.

Thus, the ORIGEN seal is the recognition of a body of work based since our beginnings - in 1969 - on three pillars: quality, respect for the environment and care for people's health. A label that is born out of the clear commitment to value the essence of our brand, Baixens.

What contribution does the ORIGIN label make to the planet?

Use of natural raw materials to the detriment of synthetic raw materials

So-called "sustainable chemistry" has been part of our DNA since our origin, opting whenever possible for natural resources, for the reduction of toxic components in formulations and for lower VOC levels.

Use of effective and efficient technology

Our R&D&I department works intensively on the formulation of ecologically advanced products which, at the same time, are of the highest quality for the professional. The products’ exigency level is not affected in the slightest.

Use of Post Consumer Recycled (PCR) plastic packaging

These containers are made from plastic waste from household, industrial, commercial and agricultural consumption and, in turn, allow for subsequent recycling. Currently, 70% of our packaging is of this nature, and we plan to achieve 100% in the very short term.

+ ENVIRONMENT

Installation of photovoltaic panels

80% of the energy used in all our manufacturing processes comes from renewable sources. In a second phase, which is already underway, we plan to install the rest of the photovoltaic panels to ensure that 100% of the energy used by Baixens is renewable.

Reducing the use of fossil fuels

· Implementation of "zero kilometre" practices. Use of local raw materials to reduce the ecological impact which their transport involves.

· Renewal of our truck fleet with I-Save technology. The incorporation of this technology reduces fuel consumption in long-haul operations. A fleet of vehicles equipped with this technology was procured in 2022.

· Complete renewal of the electric forklift fleet. The new forklifts are equipped with lithium batteries, which make them more durable and environmentally-friendly as they allow for extra-fast charging and do not generate or emit any polluting gases. It is also designed to ensure the safety of our workers.

· Installation of a free electric recharging station for employees, collaborators, customers, etc.

Recycled and recyclable packaging

-

01A sustainable production model involves incorporating plastic packaging into the circular economy, thus preventing it from becoming waste.

-

02PCR (Post Consumer Recycled) packaging is made from recycled plastics and can be recycled at a later stage.

-

03In 2021, we began the process of incorporating PCR packaging into our fillers and plasters line, as well as into our waterproofing and specific and decorative paints lines.

-

04Currently, 70% of our packaging is of this nature, and we plan to achieve 100% in the very short term.

Our environmental and health certificates endorse us

You can trust our products because they are duly audited and certified by external bodies.

ECOLABEL SEAL.

This is an accredited ecolabel awarded by the European Union to products and services that meet high environmental standards throughout their life cycle: from the extraction of raw materials to production, distribution and waste disposal.

We currently have the Ecolabel seal for all our ecological paints.

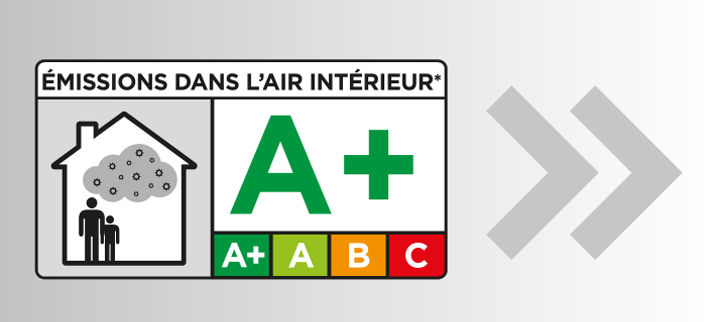

VOC EMISSIONS.

We have the environmental label for indoor air emissions class A+ on a large part of our mastics. This label, mandatory in France for construction and decoration products, identifies products (A+, A, B, C) according to their emissions of volatile organic compounds (VOCs).

ISO 14001.

We ensure that our activities and products are environmentally friendly, complying with the requirements of the ISO 14001 Environmental Management Standard.

Certification obtained in 2010.

ISO 45001.

We control occupational risks in our organisation, improving health and safety performance and complying with the requirements of the ISO 45001 Occupational Health and Safety Standard.

Certification obtained in 2013 (formerly OHSAS 18001).